Fully digitized milk storage tanks

Smart control of raw milk operations with the most accurate data you need. Remote and real-time

Monitoring and controlling the processes of the tanks remotely and in real-time without human intervention

Less fossil fuel consumption with shorter and more effective routes

Monitoring tank hygiene and improving quality control processes

Traceability, transparency, and data analysis

Reducing the carbon footprint by optimizing the most efficient use of vehicle and personnel capacities

Data-driven planning of personnel and logistics

Rawbox Watcher, patented electromechanical product, is specifically designed to be mounted on the storage tanks in the raw milk collection centers.

Volume

Volume pH

pHThe real time, 7/24 monitoring of quality ensures minimal physical intervention

Compatible with industrial computers and cloud systems

Automated mobile SMS and e-mail notifications for process updates

Data analysis and reporting with the capacity of Artificial intelligence

Advanced monitoring, tracking & admin panel

Plug & play

Plug & play Perfect accuracy

Perfect accuracy Data analysis

Data analysis Real-time data

Real-time data Sturdy design

Sturdy design CIP Compatible

CIP CompatibleWhat else would you need to know on your milk storage tanks?

All technical and operational information is now in your hands

Technology

Sensor technologies

Inline temperature, volume, pH, processes

Edge and Cloud computing

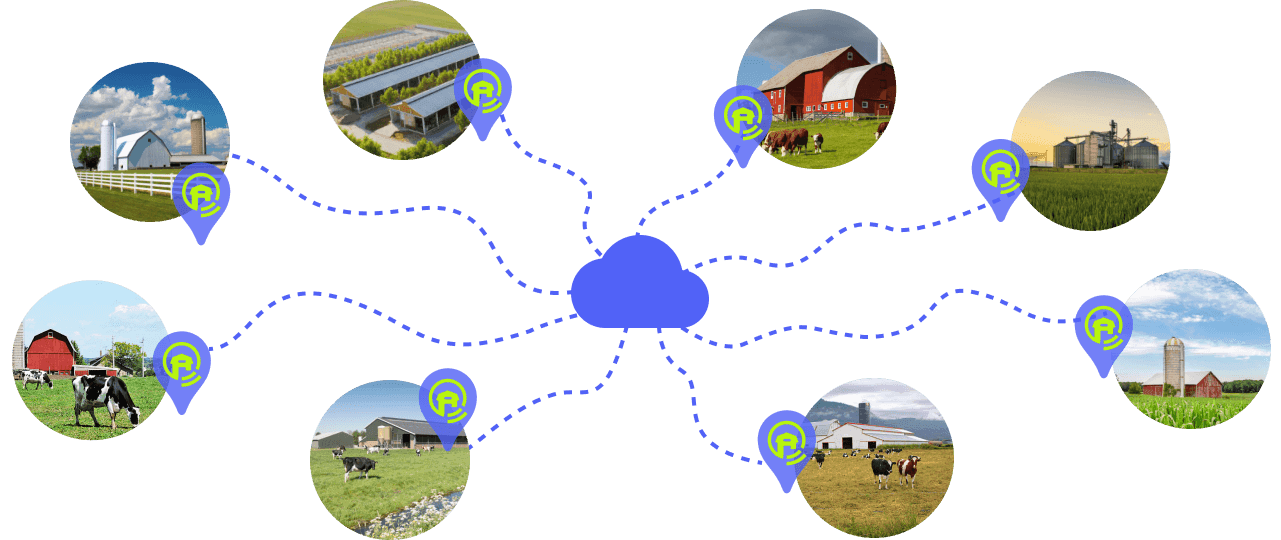

A robust architecture from edge to cloud

Notifications and alerts

Mobile and web applications

Compatible with existing equipment

Communication between manufacturer, collector and transporter

Reporting and analytics

Ease of access from anywhere anytime

Visualizing your data with charts

Integration with 3rd party services

Let's lean on sustainability, food and energy.

Reducing dependency on manual interactions and eliminating redundant routes can meet the most important demands from the dairy producers as well as logistics companies.

We create a robust and automated operations platform for the dairy industry.

We aim for a cleaner environment and high quality food.